Roll Hardness Profiles – What Can the Statistics Tell Us?

Roll Hardness Profiles – What Can the Statistics Tell Us? Quality of rolls is not about appearance – it depends

In paper, board, and other continuous production processes where the product is formed by rolling or pressing, every rotation of any mechanical element affecting the web — such as a roll, felt, wire, or pump — leaves a repeating pattern related to quality variation on the final product. These periodic patterns can manifest as variations in thickness, basis weight, ash content, density, porosity, gloss, brightness or other appearance

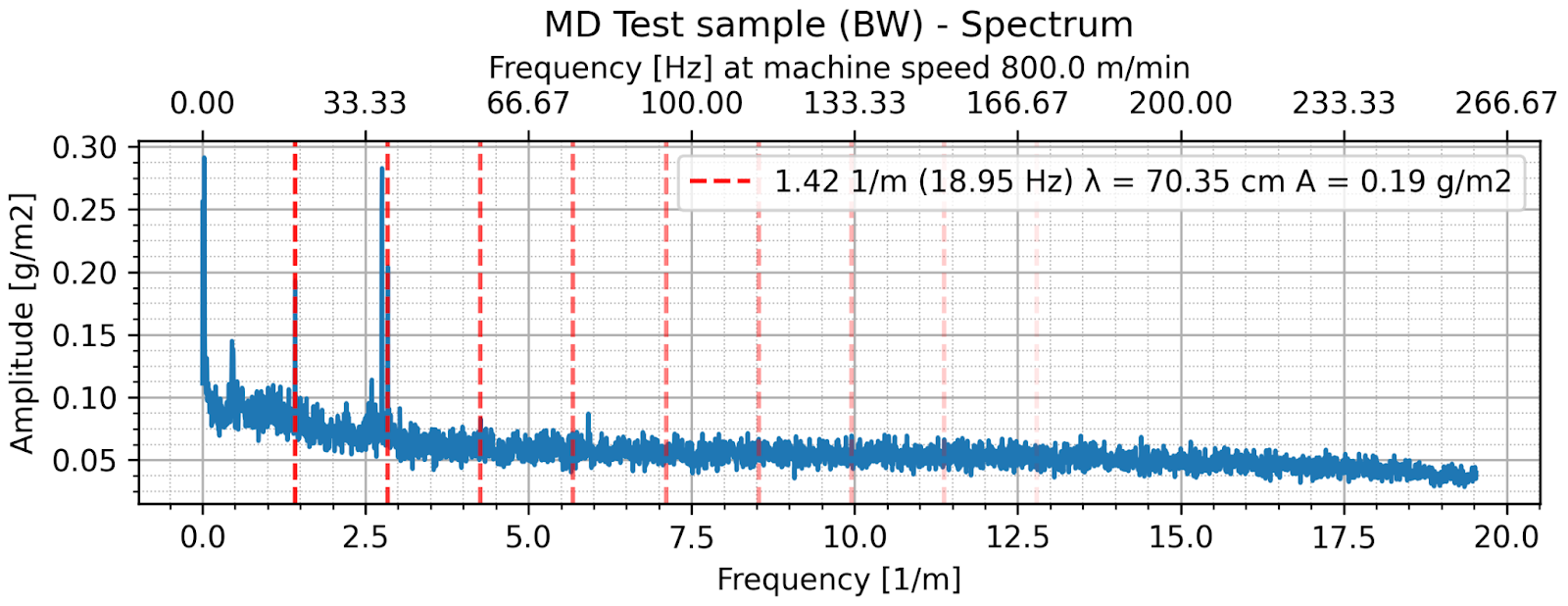

Tapio MD Analysis is a powerful, high resolution tool designed to detect and analyze these periodic patterns. By measuring the product properties along the machine direction and applying spectral (frequency domain) analysis, Tapio MD Analysis can pinpoint repeating defects with high precision.

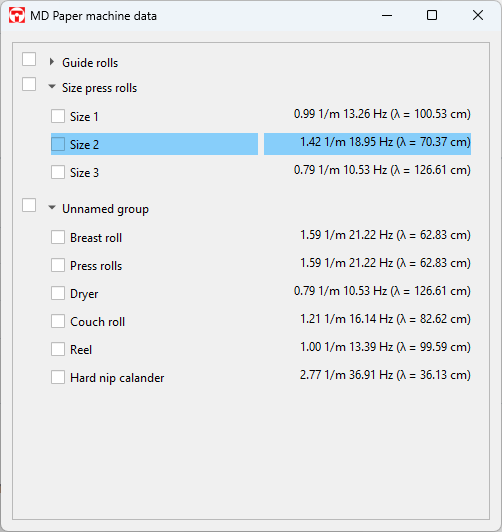

When roll diameters or rotational speeds are provided, our world-leading open-source software Tapio Analysis will automatically suggest which spectral peaks (wavelengths and frequencies of variations) most closely match the given machine elements. This feature makes it much faster and more intuitive for operators and engineers to locate the mechanical sources behind recurring defects.

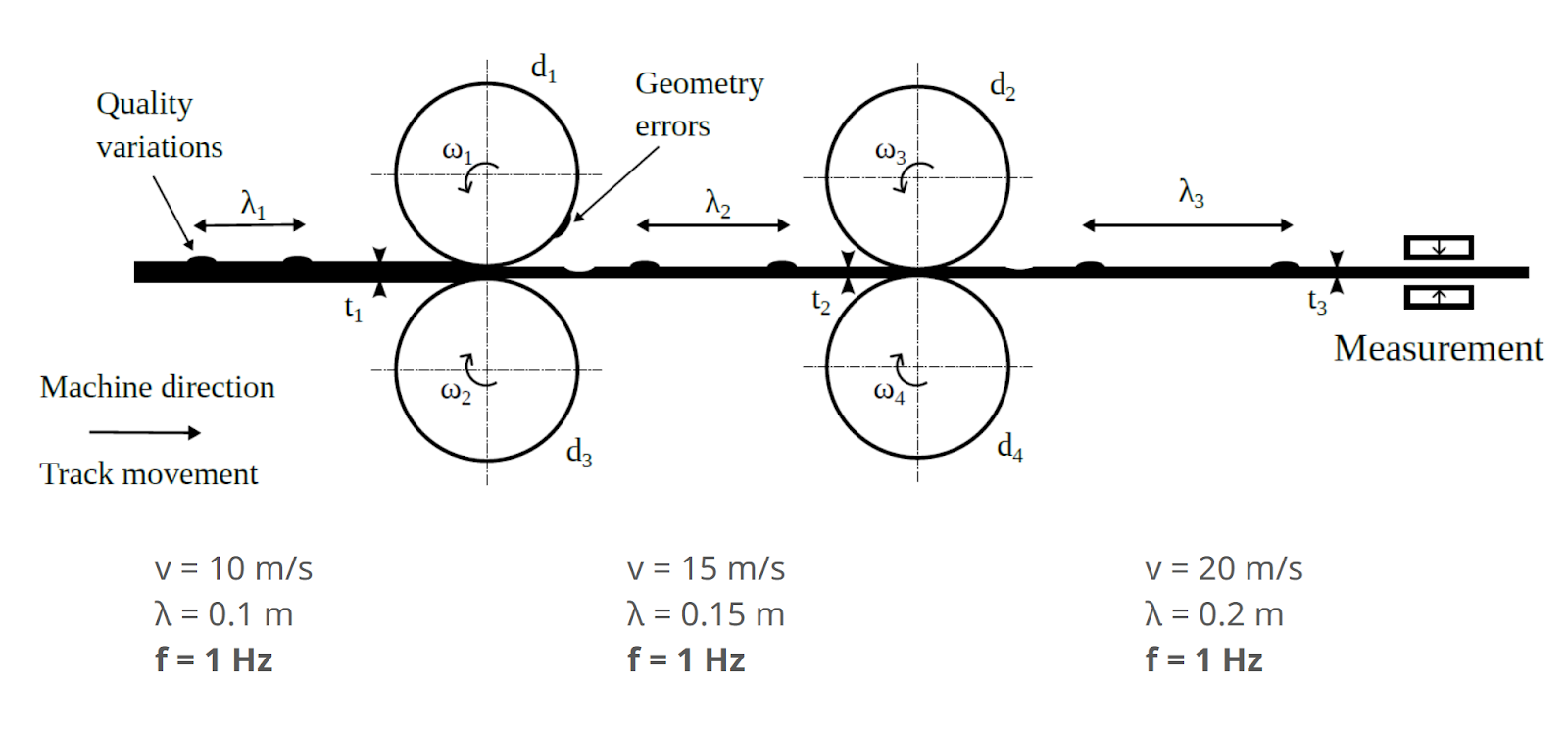

Figure: “One Hertz in Paper”. The diagram illustrates the relationship between machine speed, defect wavelength, and temporal frequency. As the web speed changes — due to acceleration or stretching along the production line — the wavelength of periodic defects increases proportionally. However, the temporal frequency — the rate at which defects pass a fixed point — remains constant. Understanding this behavior is essential for correctly linking detected patterns to machine elements.

Figure: Machine element matching in Tapio Analysis

When given roll diameters or rotational speeds, Tapio Analysis can automatically suggest which spectral peaks (rotating frequencies and wavelengths) have the closest match to the provided machine elements. This speeds up troubleshooting and enables targeted maintenance actions by pin-pointing the rolls which most contribute to the quality.

Beyond just identifying the frequency, deeper analysis is possible by using the channel-specific information available from Tapio Measurements. Tapio Analyzers measure the same point in paper with multiple sensors with small apertures and high resolution.

Available sensors include:

Additional calculated channels based on combining the data from multiple sensors, such as density, bulk, relative ash.

By analyzing in which measured property (channel) the fault appears, and studying correlations between channels, it becomes possible to narrow down the likely source of the problem, using reasoning that depends on knowledge of the specific production line:

By combining frequency and correlation analysis with reasoning based on the defect type and measurement channel, maintenance and troubleshooting efforts can be much more targeted and effective.

Roll Hardness Profiles – What Can the Statistics Tell Us? Quality of rolls is not about appearance – it depends

Optimizing paper and board machine CD profiles with Tapio Analysis In modern paper production, achieving an efficient and accurate cross-direction

Locate problematic machine elements using Tapio MD Analysis In paper, board, and other continuous production processes where the product is