Roll Hardness Profiles – What Can the Statistics Tell Us?

Roll Hardness Profiles – What Can the Statistics Tell Us? Quality of rolls is not about appearance – it depends

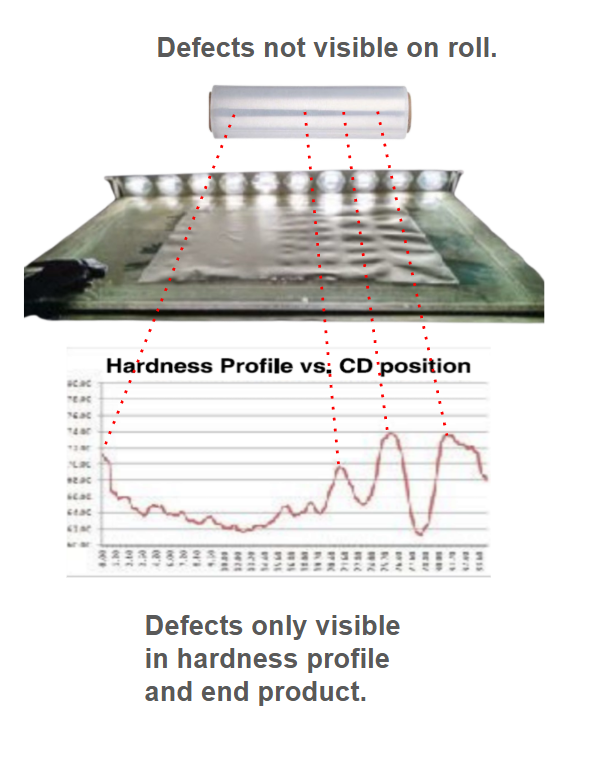

A paper, board or plastic roll may appear perfectly fine on the outside. The surface layers may seem to be uniform, smooth, and free of any obvious defects. However, beneath the outer layers, hidden issues can exist that compromise the performance and quality of the product — issues that are not immediately visible but can cause serious problems later in the process.

At Tapio Measurement Technologies, we have encountered several cases where a detailed hardness profile has revealed otherwise undetected quality problems inside the roll. In this article, we present two such cases where the use of hardness profiling was critical in identifying and addressing the issues before they escalated.

In many instances, such quality defects are not spread throughout the entire production, but are instead localized to specific sections of the roll or certain parts of the production line. For example, a loose edge or streak running through the sheet can cause significant problems later in the production and converting.

Because the defects are often confined to a specific area — such as a single edge, a localized band across the width, Tapio RQP Live can be also used to pick out the fraction of problematic rolls even from a large batch of produced rolls.

As industry demands grow, manufacturers must adopt smarter quality control methods. Relying on outdated testing techniques increases the risk of production failures. Investing in easy-to-use measurement technology ensures that every roll meets the standards – before it ever leaves your facility.

It makes sense if you think about it. Want to learn more about the impact of roll hardness on production efficiency and quality control?

The below image highlights a case where a plastic roll was initially inspected and no surface defects were observed. However, when the roll was unwound, tension differences within the film became clearly visible and observable. Inconsistent winding tension had caused localized stretching and deformation, which would have been difficult to detect without further testing.

Hidden tension variations made visible in the hardness profile

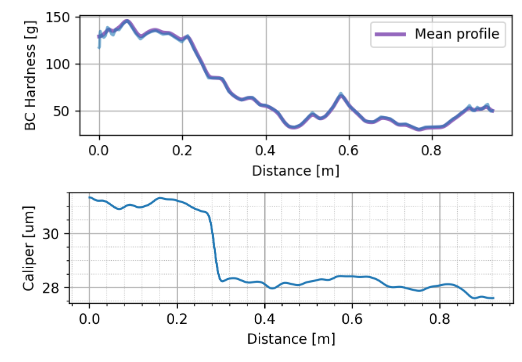

The below figure shows the measured hardness profile (top) and thickness (caliper) profile (bottom) from a polyethylene (PE) plastic film roll. The measurements reveal a strong correlation between the roll’s hardness and its thickness across the cross direction (CD) of the roll. Areas where the film thickness decreases also show a corresponding drop in hardness. This indicates that variations in film thickness during production can have a direct impact on the mechanical properties and winding quality of the roll.

By using Tapio RQP Live for regular roll hardness measurements, manufacturers can detect these variations early and trace them back to production parameters. Monitoring both hardness and thickness together provides a more complete picture of roll quality and helps in taking corrective actions where necessary.

Hardness profile and thickness profile measured from a PE plastic film roll

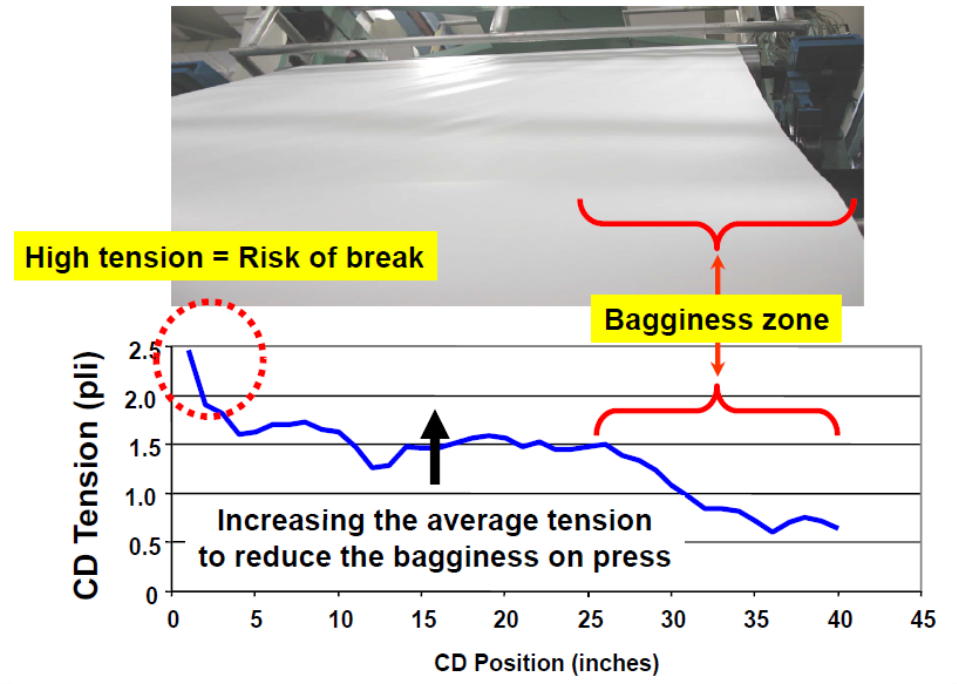

In paper production, machine rolls typically exhibit softer edges compared to the middle areas of the roll. While some degree of softness at the edges is normal and expected, it is important to understand the limits: how much hardness variation the converting process can actually tolerate without causing downstream problems.

High-resolution hardness profiles, measured with Tapio RQP Live, provide the necessary detail to clearly identify the position and severity of the soft edges. With RQP’s fine measurement resolution, operators are able to:

Common roll faults such as bagginess are clearly visible in the hardness profile of a roll.

Roll Hardness Profiles – What Can the Statistics Tell Us? Quality of rolls is not about appearance – it depends

Optimizing paper and board machine CD profiles with Tapio Analysis In modern paper production, achieving an efficient and accurate cross-direction

Locate problematic machine elements using Tapio MD Analysis In paper, board, and other continuous production processes where the product is