Quality of rolls is not about appearance – it depends both on the rolled material and on how the roll has been wound. The hardness profile provides valuable insight into roll condition and helps detect faults that are often invisible to the eye or missed by conventional methods. The traditional methods of measuring hardness are by knocking with a wooden plank or stick and listening for the loose spots – however, this requires an skilled operator and even then the decision is just quantitative.

Unlike single-point hardness testers, Tapio RQP Live produces a high-resolution profile with up to millimeter-level resolution. The device operates by gently tapping the roll surface with a hammer 25 times per second, capturing a continuous curve of hardness vs. distance. Because the tapping force is light, it does not leave harmful marks on most materials.

The hardness profile is a great indicator of overall roll quality. It can reveal common faults such as:

Detecting these issues early helps reduce production problems, avoid waste, and improve performance in the production of any rolled product.

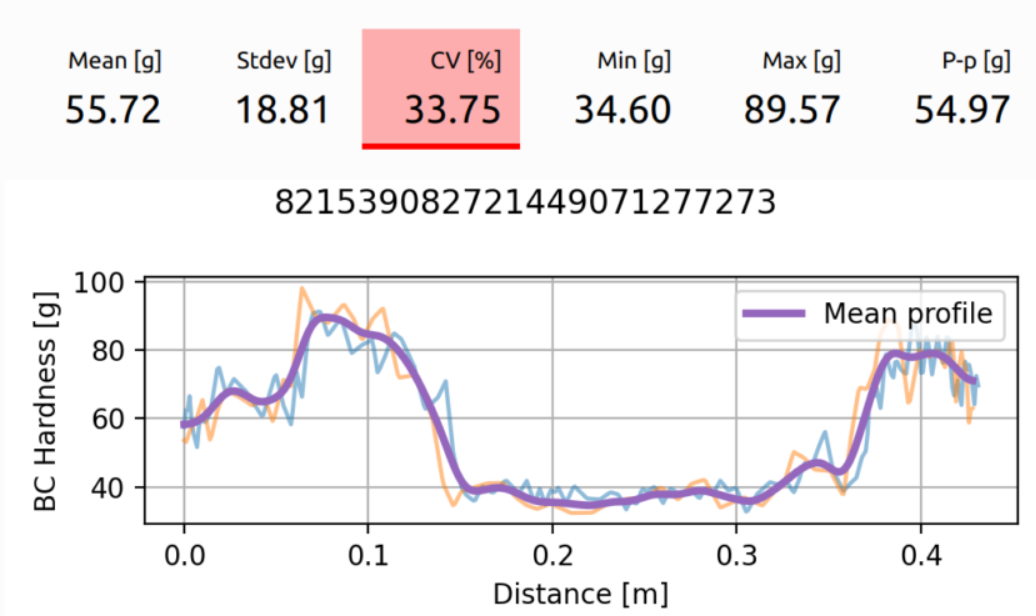

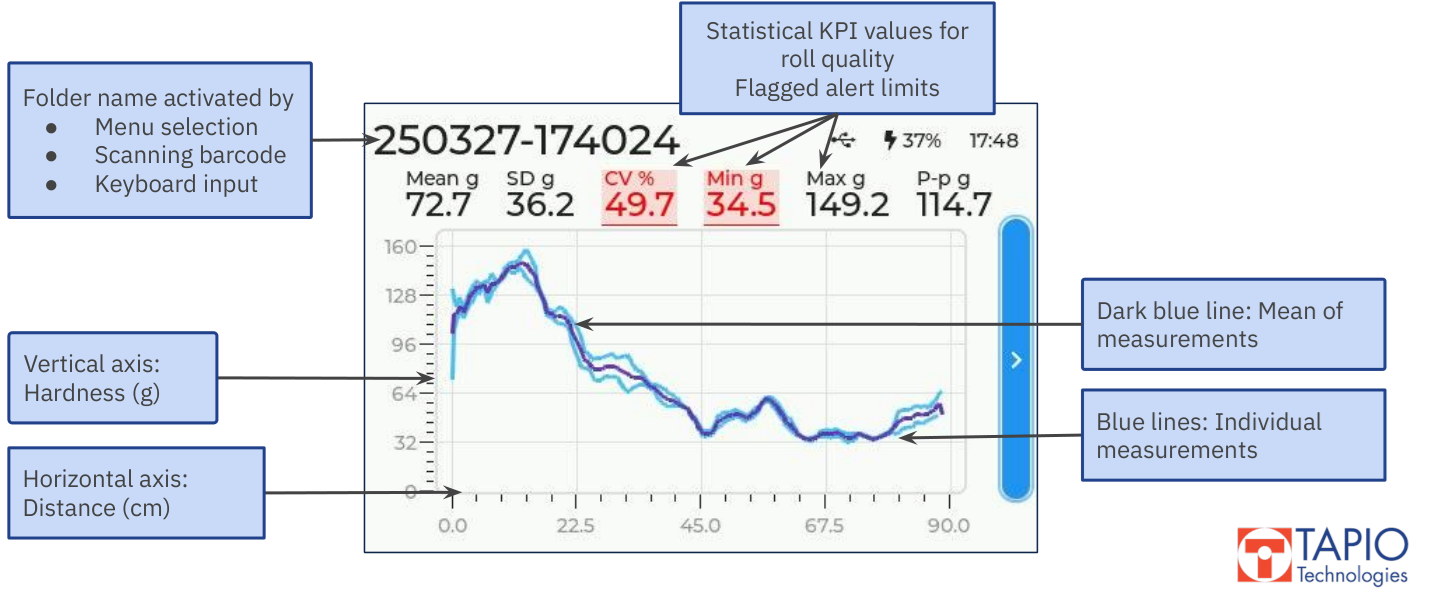

The hardness profile is displayed as a curve (consisting of the average profile of multiple measurements in case more than one have been done), showing how hardness changes across the roll width. Key statistical values are shown with the curve, making interpretation straightforward:

These values provide a quick way to judge whether a roll is uniform or if there are significant variations.

Ideally, the hardness profile would be a flat line. In practice, however, it is rarely possible to achieve a perfectly uniform profile. A well-formed roll will typically show a stable hardness profile with relatively low variation.

In the example below, the mean hardness was 72.7 g, but the coefficient of variation reached nearly 50%, with values ranging from as low as 34.5 g up to 149 g. The profile is clearly tilted, and later analysis revealed that this was caused by excessive thickness variations in the rolled plastic.

Such wide differences indicate serious issues with roll structure and can lead to significant problems during later processing. Both the RQP Live device and Tapio RollView can be configured to automatically flag problematic rolls automatically based on their profile statistics, alerting operators when unevenness exceeds acceptable limits. The exact thresholds can be adjusted according to product requirements.

The hardness profile is a practical tool for monitoring roll quality. By combining the visual profile with statistical indicators, operators can quickly spot faults, compare rolls, and make better decisions about accepting or rejecting rolls. Tapio’s RQP Live makes this information available instantly, helping mills and converters to ensure consistent quality and avoid costly roll defects.